Ultimate Guide to Best Oatmeal Chocolate Moulding Machines Featuring 10 Key Technical Specifications

In the rapidly evolving landscape of the confectionery industry, oatmeal chocolate moulding machines have emerged as pivotal equipment for manufacturers aiming to enhance production efficiency and product quality. By 2025, the global market for these specialized machines is projected to witness significant growth, driven by the rising demand for innovative chocolate products and healthier snack alternatives. According to a recent industry report, the market for moulding machines is expected to expand at a compound annual growth rate (CAGR) of 6.8%, reflecting the increasing consumer preference for convenience and premium quality in food products. This ultimate guide delves into the ten key technical specifications of the best oatmeal chocolate moulding machines available, showcasing examples that highlight their capabilities and innovations, thereby equipping manufacturers with vital insights to make informed investment decisions in this competitive sector.

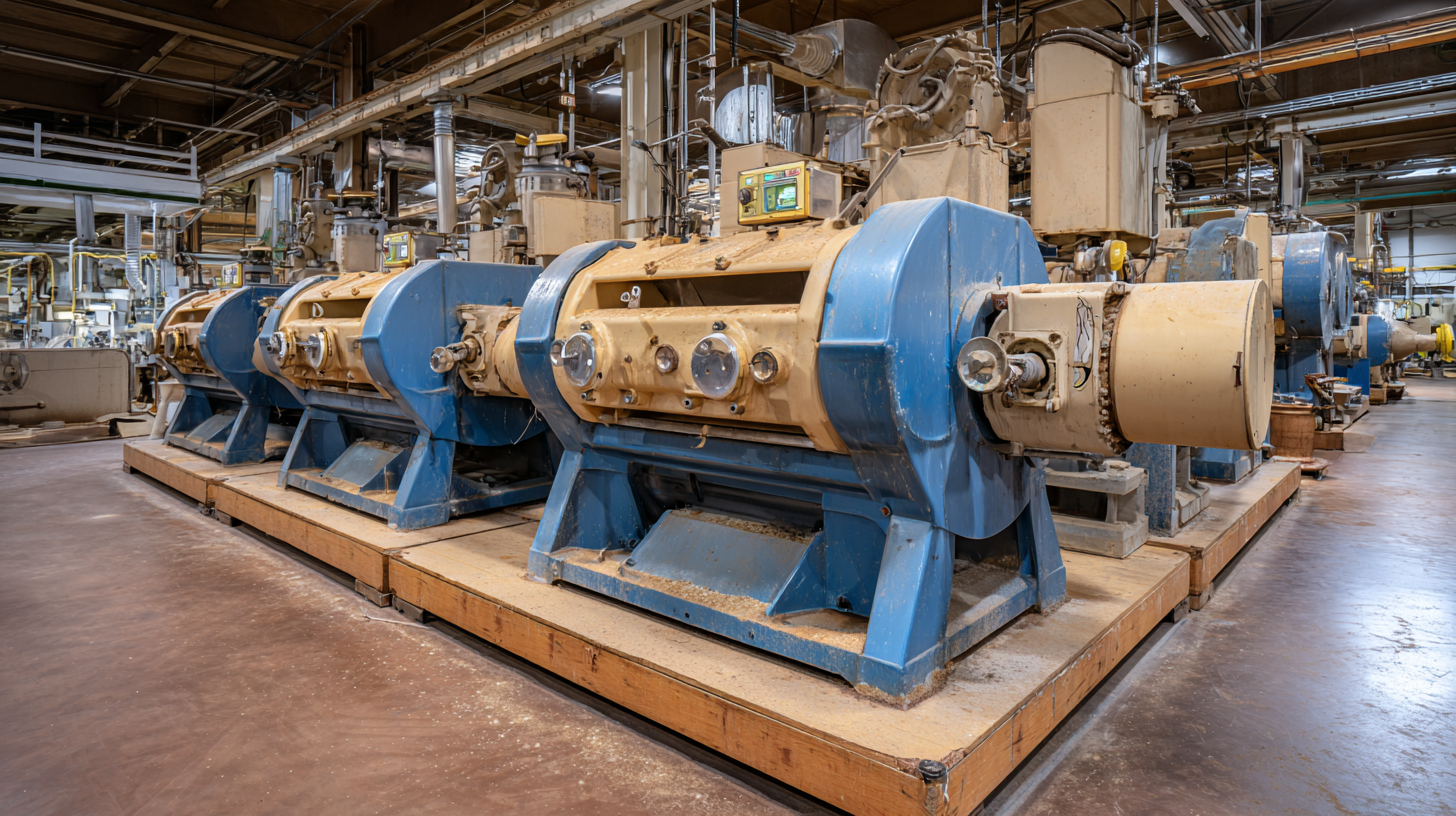

Overview of Oatmeal Chocolate Moulding Machines: A Global Perspective

Oatmeal chocolate moulding machines have become an essential component in the confectionery industry, revolutionizing the way chocolate products are made worldwide. These machines cater to a growing demand for innovative and health-conscious snacks, allowing manufacturers to create oatmeal-infused chocolate bars and treats that appeal to a wide audience. With rising consumer preferences for combining nutritious ingredients with indulgent flavors, these machines represent a significant shift towards healthier snack alternatives.

From a global perspective, the adoption of oatmeal chocolate moulding machines varies across regions, influenced by local food trends and dietary needs. In regions where health and wellness are prioritized, such as North America and Western Europe, there is a noticeable surge in the investment in these advanced machines. Manufacturers are looking for ways to streamline production while maintaining high quality, meeting the increasing demand for unique and flavorful snack options. As the market continues to evolve, machine features such as energy efficiency, versatility, and precision in moulding will play a crucial role in the competitiveness of businesses around the globe.

Key Technical Specifications Every Manufacturer Should Know

When it comes to selecting the right oatmeal chocolate moulding machines, understanding the key technical specifications can significantly enhance production efficiency and quality. Manufacturers should prioritize factors such as extrusion temperature, moulding speed, and material compatibility. According to a report by the Food Processing Machinery Association, optimal extrusion temperatures range between 70-90°C, ensuring a well-mixed product without compromising the integrity of the ingredients. Additionally, machines that feature adjustable moulding speeds can provide flexibility, accommodating a production range of 500 to 2,000 pieces per hour, catering to varying demands effectively.

Tips for manufacturers include regularly calibrating machinery to guarantee consistent product quality. Utilizing machines with user-friendly interfaces can also streamline operations, reducing training time for operators and minimizing errors. It’s essential to consider maintenance aspects; machinery with easily replaceable parts and comprehensive support can lead to lower downtime and improved productivity. Incorporating these considerations not only enhances operational efficiency but also aligns with industry best practices, ensuring that manufacturers can deliver high-quality oatmeal chocolate products consistently.

Ultimate Guide to Best Oatmeal Chocolate Moulding Machines Featuring 10 Key Technical Specifications

| Specification | Details |

|---|---|

| Machine Type | Oatmeal Chocolate Moulding Machine |

| Capacity | 500 kg/hour |

| Power Consumption | 15 kW |

| Moulding Speed | 1200 pieces/hour |

| Moulding Temperature Range | 30°C - 60°C |

| Control System | PLC & Touch Screen Interface |

| Dimensions | 2000 mm x 1500 mm x 1800 mm |

| Weight | 800 kg |

| Material | Stainless Steel |

| Warranty | 2 years |

Benefits of Upgrading Chinese-Made Oatmeal Chocolate Machines

Upgrading to modern Chinese-made oatmeal chocolate machines brings numerous benefits for manufacturers seeking improved efficiency and product quality. These machines incorporate advanced technology that streamlines the production process, significantly reducing labor costs and minimizing wastage. Enhanced precision in temperature and timing controls ensures that the chocolate maintains optimal flavor and texture, resulting in a superior product that meets consumer expectations.

When considering an upgrade, it's essential to focus on key technical specifications such as production capacity, energy efficiency, and ease of maintenance. Investing in machines with higher production capacities can lead to increased output without sacrificing quality. Moreover, selecting energy-efficient options can help cut down on operational costs, making it easier to maintain profitability in a competitive market.

Tip: Regular maintenance and prompt calibration of these machines can prolong their lifespan and enhance production reliability. Additionally, staying informed about recent technological advancements in the industry can provide insights into features that can further improve your manufacturing process. Prioritizing these aspects will ensure that you benefit maximally from your investment in oatmeal chocolate machinery.

Top Brands Leading the Oatmeal Chocolate Moulding Market

The oatmeal chocolate moulding market has seen significant innovation, driven by leading brands committed to enhancing production efficiency and product quality. Companies such as Bühler, JBT Corporation, and Chocotech are at the forefront, providing advanced machinery that meets the evolving demands of confectionery manufacturers. Each brand offers unique features that cater to varied requirements, whether for small artisanal producers or large-scale industrial operations.

Bühler’s innovations focus on versatility and scalability, allowing manufacturers to easily switch between different products while maintaining high output. JBT Corporation emphasizes automation and precision, ensuring that every moulding process is consistent and reliable. Chocotech stands out for its user-friendly designs, making it easier for operators to manage complex processes without extensive training. These top brands not only lead in technological advancements but also provide robust support and service options, making them invaluable partners in the oatmeal chocolate moulding industry.

Future Trends in Oatmeal Chocolate Moulding Technology and Manufacturing

The future of oatmeal chocolate moulding technology is on the cusp of a transformative leap, driven by advancements in smart manufacturing and the integration of artificial intelligence (AI). According to Deloitte's recent survey, a staggering 95% of global manufacturers are expected to invest in AI and machine learning technologies within the next five years. This trend will enhance the efficiency and customization capabilities of oatmeal chocolate moulding machines, allowing for highly precise production processes that cater to evolving consumer tastes.

As the manufacturing sector navigates through volatility and cyclical recovery, the demand for agile and adaptive production methods is increasing. The 2025 Manufacturing Industry Outlook report highlights that organizations are focusing on overcoming challenges related to talent acquisition and operational efficiency. In this context, the incorporation of smart technologies into the design and operation of moulding machines can lead to significant improvements in productivity and cost-effectiveness. Additionally, process analytical technologies (PAT) are emerging as crucial tools to ensure quality and safety in food manufacturing, setting the stage for a new era of oatmeal chocolate production that is both innovative and sustainable.