Ultimate Guide to Choosing the Best Chocolate Depositing Machine for Your Factory

The chocolate industry has witnessed significant growth over the past few years, with the global chocolate market expected to reach approximately $180 billion by 2024, according to recent industry reports. This surge in demand necessitates efficient production processes, making the choice of equipment crucial for manufacturers. One essential piece of machinery is the chocolate depositing machine, which plays a vital role in delivering precision, consistency, and quality in chocolate production.

By automating the depositing process, these machines not only enhance productivity but also reduce labor costs, ensuring that factories can meet the rising consumer expectations for innovative chocolate products. As you embark on the journey to choose the best chocolate depositing machine for your factory, understanding the key features and benefits of these machines is paramount to achieving operational excellence in an increasingly competitive market.

Understanding the Various Types of Chocolate Depositing Machines

When selecting the right chocolate depositing machine for your factory, it is crucial to understand the various types available in the market. Chocolate depositing machines can be broadly categorized into two main types: gravity-fed and piston-type machines. Gravity-fed machines are ideal for less viscous chocolate, as they allow for a continuous flow through the nozzle, resulting in smooth, consistent deposits. According to a 2022 industry report, approximately 54% of chocolate manufacturers prefer this type due to its simplicity and efficiency in handling basic shapes and designs.

On the other hand, piston-type depositing machines are designed for thicker chocolate masses and are often used for more intricate designs. These machines operate using a precision piston mechanism, which provides better control over the volume of chocolate dispensed. Recent market research indicates that nearly 36% of large-scale manufacturers have shifted towards piston-type machines, especially for producing filled chocolates and complex molds. Understanding these distinctions and your production needs will better position you to choose a chocolate depositing machine that optimally enhances your manufacturing capabilities.

Key Features to Look for in Chocolate Depositing Equipment

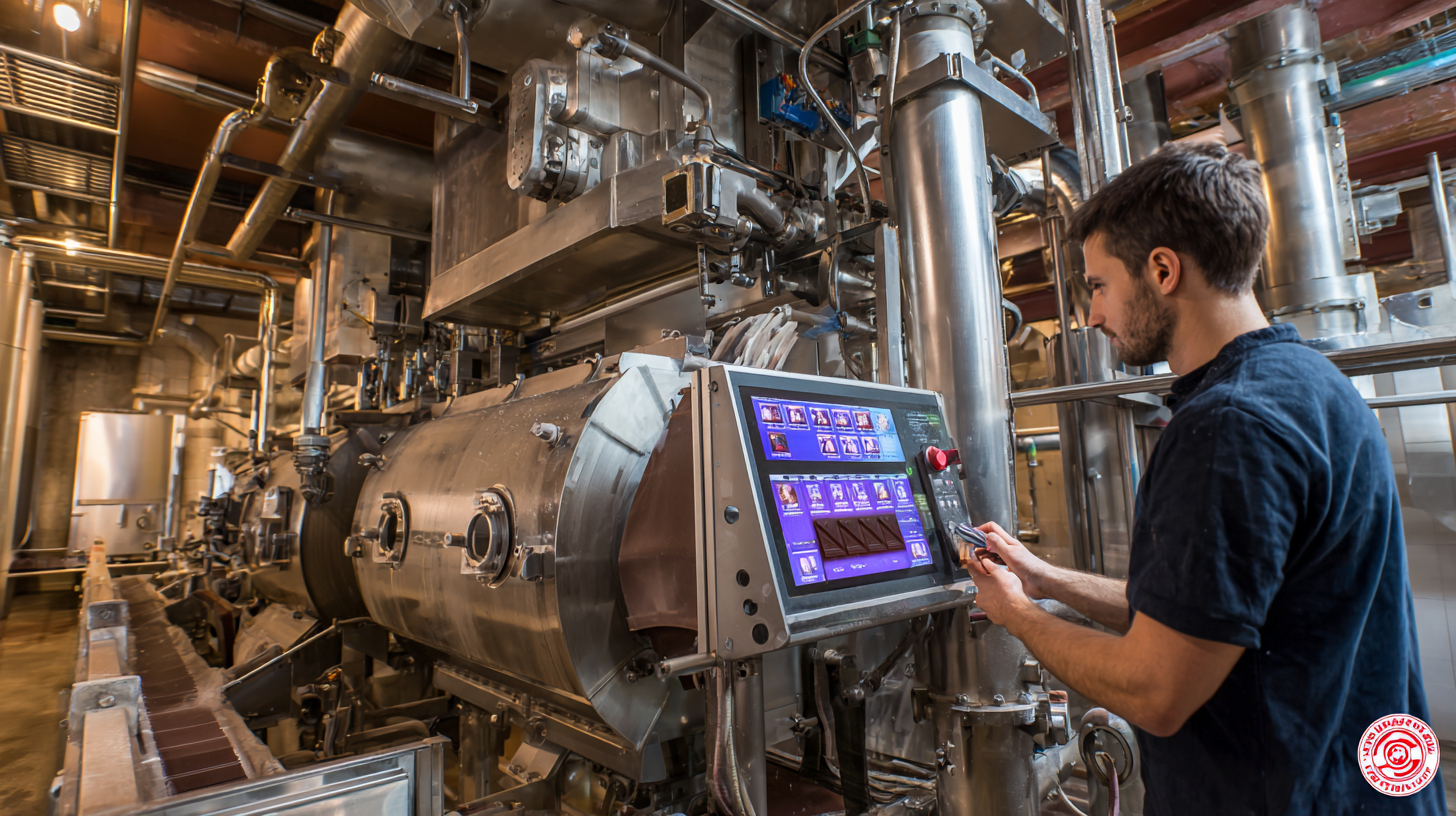

When selecting a chocolate depositing machine for your factory, it's essential to understand the key features that will enhance your production efficiency and product quality. First and foremost, consider the machine's temperature control system. Chocolate requires precise temperature regulation to ensure optimal flow and prevent crystallization. A high-quality depositing machine should have advanced heating and cooling mechanisms that maintain consistent temperatures, allowing for superior chocolate quality and reduced production downtime.

Another critical feature to evaluate is the machine's versatility. A good chocolate depositing machine should accommodate a variety of chocolate types and formulations, including milk, dark, and white chocolate. Additionally, it should be capable of handling inclusions like nuts or fruit pieces, offering flexibility for your product range. Automatic switching between different depositing modes is also a beneficial aspect that enhances operational efficiency, enabling quick adjustments for diverse production runs without compromising quality.

Finally, look for user-friendly controls and automation features. A sophisticated control panel that provides real-time monitoring and easy operation can significantly reduce the learning curve for your staff. Moreover, machines equipped with automation capabilities can streamline production processes, minimize manual labor, and ensure consistent product results. Investing in a chocolate depositing machine that combines these essential features will not only boost your factory's productivity but also elevate the overall quality of your chocolate products.

Ultimate Guide to Choosing the Best Chocolate Depositing Machine for Your Factory

| Feature | Description | Importance |

|---|---|---|

| Production Capacity | Measured in kilograms per hour, indicating how much chocolate can be deposited in a given time. | High |

| Temperature Control | Ability to maintain optimal chocolate temperature for smooth depositing. | High |

| Versatility | Capability to handle different types of chocolates and inclusions. | Medium |

| Ease of Cleaning | Design that allows for quick and thorough cleaning between production runs. | High |

| User Interface | Intuitive controls for ease of operation by factory workers. | Medium |

| Size and Footprint | Physical dimensions of the machine and its space requirements in the factory. | Medium |

| Durability | Quality of materials and engineering to withstand high-volume production. | High |

Comparing Automatic vs. Manual Chocolate Depositing Machines

When it comes to selecting a chocolate depositing machine for your factory, understanding the key differences between

automatic and manual models is crucial.

Automatic chocolate depositing machines streamline the production process, allowing factories to increase efficiency and consistency.

These machines offer precise control over the depositing process, enabling higher output rates and reduced human error. Their advanced technology often includes

programmable settings that can accommodate various production needs, making them suitable for high-volume operations.

When it comes to selecting a chocolate depositing machine for your factory, understanding the key differences between

automatic and manual models is crucial.

Automatic chocolate depositing machines streamline the production process, allowing factories to increase efficiency and consistency.

These machines offer precise control over the depositing process, enabling higher output rates and reduced human error. Their advanced technology often includes

programmable settings that can accommodate various production needs, making them suitable for high-volume operations.

On the other hand, manual chocolate depositing machines provide more hands-on control. They are typically

more affordable and ideal for smaller businesses or artisanal chocolate makers who prioritize craftsmanship

over mass production. With manual machines, operators can adjust techniques and consistency based on real-time feedback, which can be beneficial for experimenting

with different flavors or shapes. While they may require more labor and time investment, manual machines can result in unique, custom products that stand out

in a competitive market. Ultimately, the choice between an automatic and manual machine will depend on your factory’s production goals, budget, and desired

product offerings.

Evaluating Production Capacity: Choosing the Right Size Machine

When selecting a chocolate depositing machine for your factory, evaluating production capacity is critical. The machine's size must align with your production goals, ensuring you can meet demand without sacrificing quality. Start by assessing your output requirements — consider how many chocolates you plan to produce weekly or monthly. This information will guide you in determining the machine's capacity, typically rated in kilograms per hour, to prevent bottlenecks in your production line.

Additionally, consider future growth when choosing a machine's size. If you anticipate an increase in production needs or plan to expand your product line, investing in a larger machine could save you from needing an upgrade shortly after purchase. However, a too-large machine may lead to inefficiencies and excess energy consumption. Striking a balance between current needs and future scalability is essential for optimizing both productivity and cost-effectiveness in the long run.

Chocolate Depositing Machine Production Capacity

Budget Considerations for Investing in a Chocolate Depositing Machine

When considering an investment in a chocolate depositing machine, budgeting plays a crucial role in the decision-making process. The first step is to assess the initial costs associated with the machines, which can vary significantly based on their size, brand, and features. It's essential to strike a balance between functionality and cost-effectiveness; expensive machines may not always offer the best value if they don't align with your production needs. Conducting thorough research on different models and what they offer can help you identify which machines provide the best return on investment.

Additionally, it's important to factor in ongoing expenses such as maintenance and operation costs. A more affordable machine might come with higher energy consumption or require more frequent servicing, leading to increased long-term expenditures. Budgeting should also take into account the potential need for upgrades or additional features in the future, as your production may grow or change over time. By planning for both the initial and future costs, you can make a more informed decision that ensures your chocolate depositing machine is a wise investment for your factory.