How to Choose the Right Motorized Valve for Your Needs?

Choosing the right Motorized Valve can be challenging. With various options available, it’s easy to feel overwhelmed. A Motorized Valve effectively controls the flow of fluids in HVAC systems, water treatment, and industrial processes. Selecting one requires careful consideration of specific needs.

Consider the application requirements. Is it for heating, cooling, or water management? Each use might demand different specifications. Assess the environment too. Factors like temperature and pressure play a vital role in performance. Understand the torque and power requirements of the Motorized Valve as well. This understanding helps in avoiding underperformance.

Don’t overlook the long-term benefits. A well-chosen Motorized Valve enhances efficiency and reliability. However, if you rush the decision, you might face costly repairs or replacements. Reflect on how these choices impact your operations. Taking the time to analyze your needs will yield better results.

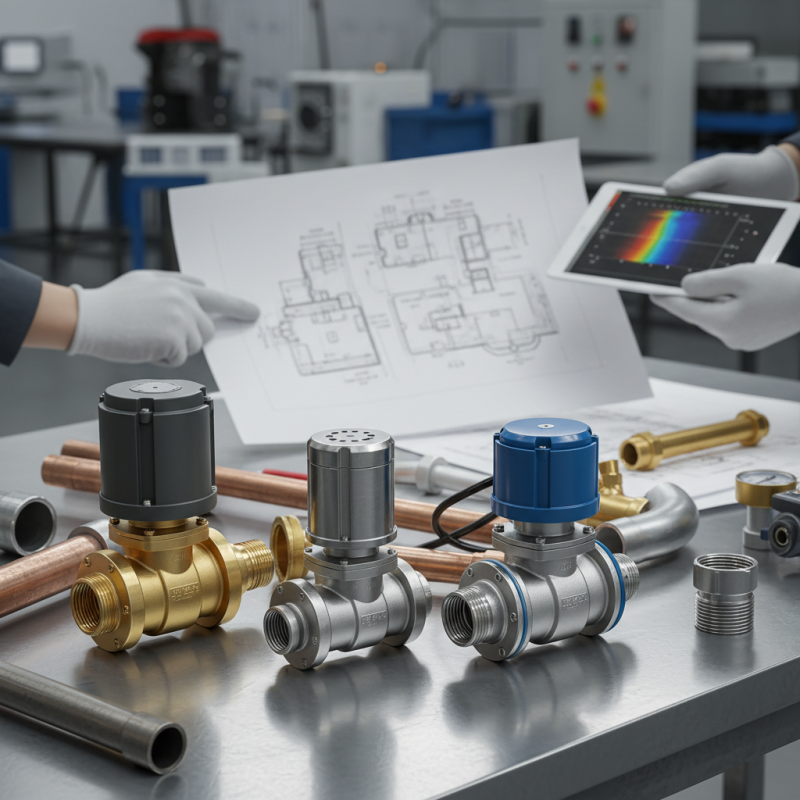

Types of Motorized Valves and Their Applications

Motorized valves are essential in various industrial applications. They automate fluid control, offering precision and reliability. There are several types of motorized valves, each suited to specific tasks. For instance, ball valves are known for their quick operation and low pressure drop. They can handle viscous fluids well, making them ideal for chemical processing. According to a recent industry report, these valves account for approximately 40% of the global motorized valve market.

Another common type is the globe valve. This valve provides excellent flow regulation but may create more resistance in the system. Notably, globe valves are widespread in HVAC applications. Recent forecasts indicate that the demand for globe valves could grow by 5% annually, driven by energy efficiency regulations. Despite their advantages, some users find installations complex. This complexity may require additional training for operational staff.

Lastly, butterfly valves are lightweight and compact. They excel in handling large volumes of fluid. They're popular in water treatment facilities. A study highlighted that butterfly valves offer up to 20% savings in material costs compared to traditional valve types. However, users must be cautious. Improper installation may lead to leakage or system inefficiencies, necessitating further evaluation. Understanding these varieties will help in selecting the right motorized valve for your specific needs.

Key Factors to Consider When Choosing a Motorized Valve

When selecting a motorized valve, several key factors come into play. Understanding the specific application is crucial. Different systems require unique features. For instance, a report by the International Society of Automation noted that incorrect valve selection could lead to efficiency losses of up to 25%. This emphasizes the importance of accurate identification of flow requirements and pressure ratings.

Material choice is another critical aspect. Motorized valves are available in various materials, including stainless steel and plastic. Each material has its advantages and disadvantages. The right material can significantly affect lifespan and resistance to corrosion. According to industry data, valves made from high-grade materials can outperform cheaper alternatives by up to 40% in durability.

Actuation type is also vital. Electric, pneumatic, and hydraulic actuation methods serve different operational needs. Electric actuators, for example, offer precise control but may require more maintenance. In contrast, pneumatic actuators can handle high flow rates but may need constant air supply. This variance highlights the importance of balancing performance and reliability according to your operational context. An ill-suited actuator can lead to frequent downtime and inefficiencies.

Understanding Valve Actuation Methods and Mechanisms

When selecting a motorized valve, understanding actuation methods is crucial. The three main types are electric, pneumatic, and hydraulic actuation. Electric actuators are popular for their precise control. They work efficiently in various applications, whether for heating or cooling systems. However, they may require more maintenance.

Pneumatic actuators operate on compressed air. They offer quick response times and high speed. Yet, they can be less precise than electric models. Users should consider the availability of air supply and potential noise levels as well. Hydraulic actuators use fluid pressure to function. They can handle larger valves but may incur higher operational costs.

When choosing, think about your specific needs. What is the environment like? Will the valve be exposed to harsh conditions? These factors affect actuator performance. Sometimes, the desired response time conflicts with energy efficiency. Finding the right balance can be challenging. Evaluate all options carefully. Each method has trade-offs that warrant consideration.

Sizing and Specifications: Ensuring Compatibility with Your System

Choosing the right motorized valve involves careful consideration of sizing and specifications. The flow rate is critical. It should match your system’s requirements. For instance, a system with a flow rate of 50 gallons per minute needs a different valve than one with a rate of 10 gallons per minute. Industry reports suggest that mismatching these can lead to inefficient operations.

Pressure rating is equally important. It defines how much pressure the valve can handle. A valve rated for 150 psi may fail in a system with 200 psi. This can lead to catastrophic leaks. Understanding your system’s pressure demands is essential. Data from engineering studies show that almost 30% of system failures stem from incorrect valve pressure ratings.

Another factor to consider is the actuator type. Electric and pneumatic actuators serve different applications. Electric actuators are more precise, while pneumatic actuators can respond faster. But their energy consumption varies greatly. A poor choice in actuator can add unnecessary costs to operations. Reflecting on these elements will guide your selection process effectively.

Maintenance and Longevity: Selecting Durable Motorized Valves

When selecting a motorized valve, durability should be a top priority. A high-quality valve can last many years with proper care. Look for robust materials that can withstand harsh conditions. Stainless steel, for example, resists corrosion and wear, making it a solid choice. However, don't overlook the importance of seals and gaskets. They play a crucial role in preventing leaks and maintaining efficiency.

Maintenance is key to longevity. Regularly checking for leaks or operational issues can save significant costs later. Some users might neglect this aspect, assuming that a durable valve won’t need attention, but that's a risky mindset. For instance, a small leak can lead to extensive damage over time. Regular maintenance can often reveal hidden issues before they escalate, ensuring the valve performs optimally.

Consider installation factors as well. Improper installation can lead to premature failure, even with a durable valve. Ensure that the valve is correctly aligned and secured. Reviewing installation procedures can prevent future headaches. Reflect on past experiences with other valves; what could have been improved? This introspection can guide better choices today, ensuring a reliable and long-lasting system.

How to Choose the Right Motorized Valve for Your Needs? - Maintenance and Longevity: Selecting Durable Motorized Valves

| Valve Type | Material | Temperature Range (°C) | Pressure Rating (MPa) | Application | Expected Lifespan (Years) |

|---|---|---|---|---|---|

| Ball Valve | Stainless Steel | -20 to 150 | 1.6 | Water Supply | 10 |

| Butterfly Valve | PVC | 0 to 60 | 0.6 | Chemical Processing | 5 |

| Gate Valve | Cast Iron | -10 to 110 | 1.0 | Oil & Gas | 15 |

| Globe Valve | Brass | -20 to 120 | 1.0 | HVAC Systems | 10 |

| Check Valve | Aluminum | -30 to 140 | 1.6 | Water Treatment | 8 |