How to Maximize Chocolate Production Efficiency with a Chocolate Depositing Machine

In the ever-evolving chocolate manufacturing industry, maximizing production efficiency is critical to meet soaring consumer demand, which has reportedly increased by 12% over the past five years, according to a recent industry analysis by Mordor Intelligence. A crucial player in achieving this efficiency is the "Chocolate depositing machine," a specialized apparatus designed to streamline the chocolate production process. By ensuring precise portioning, reducing waste, and enhancing production speed, these machines not only improve operational efficiency but also significantly impact profit margins. The global chocolate market, valued at approximately $131.2 billion in 2019, is projected to reach $187.5 billion by 2024, highlighting the urgent need for manufacturers to adopt advanced technology such as chocolate depositing machines to stay competitive and meet the demands of a dynamic market. This introduction sets the stage for exploring effective strategies to leverage such machinery for optimal production outcomes.

Understanding the Basics of Chocolate Depositing Machines for Enhanced Efficiency

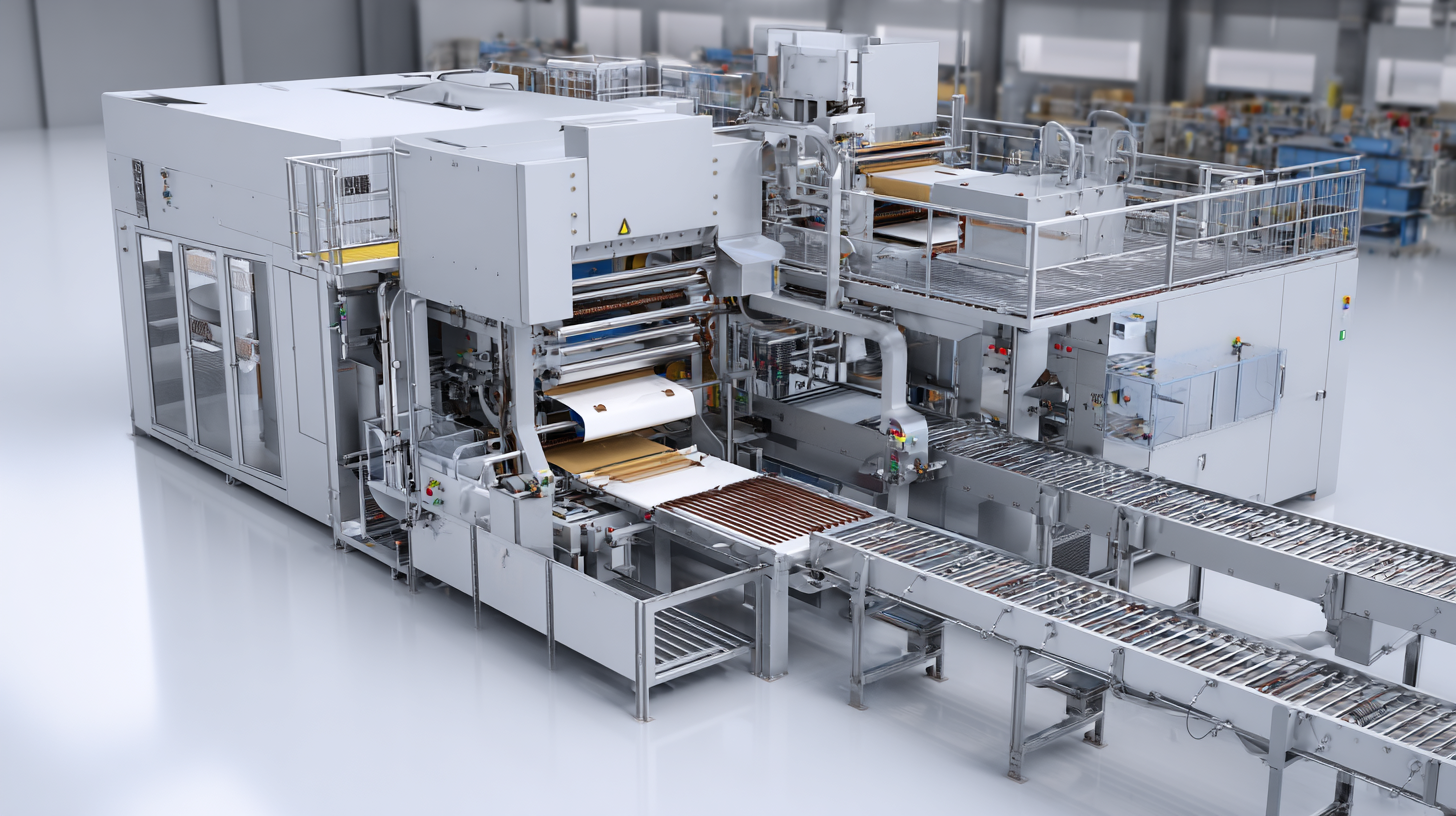

Understanding the basics of chocolate depositing machines is crucial for maximizing production efficiency in any chocolate-making venture. These specialized machines streamline the process of molding and depositing chocolate into shapes, significantly reducing the time and labor required compared to manual methods. By ensuring precise control over temperature and flow, chocolate depositing machines help minimize waste while enhancing the overall quality of the final product. This is essential for chocolatiers aiming to maintain high standards in their offerings while meeting increasing market demands.

In addition, the integration of advanced technologies in chocolate depositing machines is reshaping how businesses operate. Features such as automatic tempering and programmable settings allow chocolatiers to produce consistent results, whether they’re crafting complex designs or simple molds. As the chocolate market continues to evolve, investing in these machines not only leads to higher efficiency but also opens up new opportunities for creativity and innovation in product offerings. Being aware of these technological advancements is key for anyone looking to stay competitive in the evolving chocolate industry.

Chocolate Production Efficiency Analysis

Key Features to Look for in a High-Performance Chocolate Depositing Machine

When selecting a high-performance chocolate depositing machine, several key features should be prioritized to ensure optimal efficiency in production. First and foremost, the machine’s accuracy in depositing chocolate is crucial. Look for machines that offer adjustable nozzles and precise control systems to ensure consistent portioning. This precision not only enhances product quality but also reduces waste, contributing to a more cost-effective operation.

Another important feature to consider is the machine's versatility. A high-performance chocolate depositing machine should be capable of handling various types of chocolate, including dark, milk, and white, as well as offer the flexibility to incorporate inclusions such as nuts or fruit. Additionally, the machine should allow for quick changeovers between different products, minimizing downtime and maximizing production output. Finally, an efficient heating and cooling system is essential to maintain the ideal chocolate tempering, ensuring smooth flow and proper setting of the finished products. These features combine to create a reliable and efficient chocolate depositing machine that can enhance overall production processes.

Optimal Setup and Maintenance Practices for Chocolate Deposit Machines

To ensure optimal performance of chocolate depositing machines, it is essential to follow specific setup and maintenance practices. Initially, accurate calibration of the machine is crucial. This involves setting the correct temperature for the chocolate, which should be maintained between 30-32°C for dark chocolate and slightly lower for milk or white chocolate. Proper alignment of the depositing nozzles and adjusting the timing mechanisms will also enhance the precision of the chocolate flow, minimizing waste and ensuring consistent product quality.

Regular maintenance is another key aspect that cannot be overlooked. Cleaning the machine daily after production helps prevent chocolate build-up and cross-contamination of flavors. It’s advisable to use food-safe detergents and warm water for a thorough clean. Furthermore, periodically inspecting components such as pumps, belts, and heating elements can preemptively address issues that might lead to downtime. Keeping a maintenance log can assist operators in identifying patterns or recurrent problems, enabling timely interventions before they escalate into major repairs. Implementing these practices will significantly increase the efficiency and longevity of chocolate depositing machines.

Effective Production Workflow Strategies to Boost Chocolate Output

Maximizing chocolate production efficiency begins with an effective workflow that leverages the capabilities of chocolate depositing machines. In the chocolate manufacturing industry, it is reported that automated depositing can increase production speed by up to 30%, significantly impacting overall output. Implementing a streamlined workflow that integrates machine capabilities with production needs can ensure that manufacturers meet rising consumer demand without sacrificing quality.

Incorporating real-time data monitoring and predictive maintenance strategies can drastically reduce downtime. According to a recent industry report by Technavio, manufacturers that adopted smart technology experienced a 15% decrease in machine failures, facilitating smoother operations and allowing for increased throughput. Additionally, reorganizing production lines to minimize material handling time can enhance efficiency, with some facilities reporting a 20% increase in output when processes are adapted for optimal flow. By focusing on these effective production workflow strategies, chocolate producers can cultivate a robust operation that ensures high-quality products while meeting the demands of the market.

Innovative Techniques to Minimize Waste During Chocolate Production

In the chocolate production industry, minimizing waste is crucial not only for enhancing efficiency but also for improving profitability. Recent reports indicate that chocolate manufacturers can incur up to 10% waste during various production stages, including mixing, pouring, and cooling (source: International Chocolate Research Institute). One innovative technique to combat this issue is implementing a chocolate depositing machine that can accurately control the quantity of chocolate dispensed. Such precision reduces overpouring and ensures that every batch meets quality standards while significantly decreasing leftover material.

Additionally, employing advanced data analytics can help producers identify waste patterns. By analyzing production workflows, manufacturers can optimize machine settings and adjust processes accordingly. A study by the Chocolate Manufacturing Efficiency Council highlights that businesses leveraging data analytics have successfully reduced waste by 15% on average. Integrating these innovative approaches not only contributes to a more sustainable production model but also aligns with consumer demands for responsible sourcing and production practices, ultimately enhancing brand loyalty and market share.

Related Posts

-

Understanding Global Standards for Advanced Chocolate Machines and How to Choose the Best One

-

Ultimate Guide to Choosing the Right Chocolate Depositing Machine for Your Factory

-

7 Compelling Reasons to Invest in a Chocolate Depositing Machine for Your Business Success

-

The Ultimate Guide to Choosing the Perfect Chocolate Machine for Your Business

-

Discover Cutting Edge Chocolate Depositing Machines at the 137th Canton Fair 2025

-

How to Identify the Best Chocolate Machine Manufacturer for Your Business Needs