Exploring the Technical Specifications of the Best Chocolate Machine for Global Buyers

The global chocolate market has been experiencing remarkable growth, with reports indicating an anticipated

compound annual growth rate (CAGR) of over 4%

from 2022 to 2027. This surge in demand underscores the importance of high-quality chocolate production,

leading to an increased focus on advanced chocolate machines that can meet stringent industry standards.

In this realm, the exploration of various types of chocolate machines is crucial for manufacturers aiming to enhance efficiency and product quality.

From tempering to molding and enrobing, each machine plays a pivotal role in the chocolate-making process.

Understanding the technical specifications of these chocolate machines enables global buyers to make informed decisions tailored to their operational needs,

ensuring they remain competitive in a thriving market.

The global chocolate market has been experiencing remarkable growth, with reports indicating an anticipated

compound annual growth rate (CAGR) of over 4%

from 2022 to 2027. This surge in demand underscores the importance of high-quality chocolate production,

leading to an increased focus on advanced chocolate machines that can meet stringent industry standards.

In this realm, the exploration of various types of chocolate machines is crucial for manufacturers aiming to enhance efficiency and product quality.

From tempering to molding and enrobing, each machine plays a pivotal role in the chocolate-making process.

Understanding the technical specifications of these chocolate machines enables global buyers to make informed decisions tailored to their operational needs,

ensuring they remain competitive in a thriving market.

Key Features to Look for in Top Chocolate Machines for 2025

When considering the best chocolate machines for 2025, buyers should focus on several key features that align with industry trends and user needs. According to a report by Grand View Research, the global chocolate machinery market is anticipated to reach approximately $5 billion by 2025, highlighting the increasing demand for high-quality production equipment. One primary feature to assess is the machine's automation capabilities. With the rising trend of smart manufacturing, machines equipped with IoT technology offer streamlined processes and enhanced control, ensuring consistency and efficiency in chocolate production.

Another critical aspect is the versatility of the machine. Top manufacturers are now producing machines that can handle various chocolate types and shapes, catering to a diverse market. A survey by the Equipment Manufacturers Association reveals that 68% of chocolate makers prioritize flexibility in their production lines to adapt to changing consumer preferences. Additionally, energy efficiency is becoming paramount, as sustainability plays an increasingly vital role in production. Investing in machines that boast lower energy consumption is not only eco-friendly but also helps manufacturers reduce operational costs. Consider these features carefully to ensure that your chocolate machine remains relevant in an evolving industry landscape.

Advancements in Chocolate Machine Technology: What Buyers Need to Know

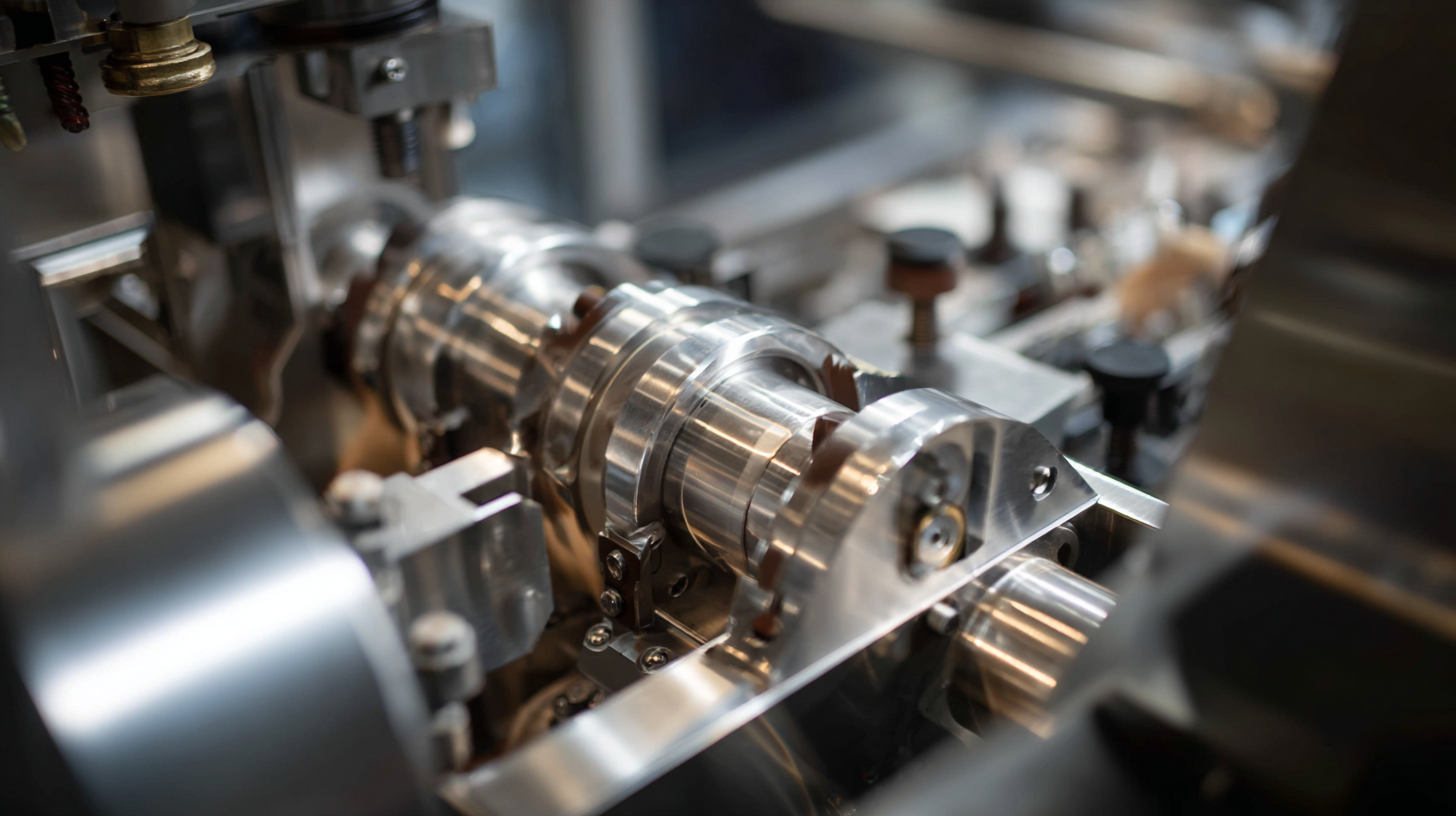

The chocolate machine industry has seen remarkable advancements in technology, greatly enhancing production efficiency and product quality. Modern machines now incorporate cutting-edge features such as automated tempering, precise temperature control, and smart monitoring systems. These innovations not only streamline the manufacturing process but also ensure that the final products maintain their rich flavor and silky texture. Buyers looking for the best chocolate machines must consider these technological upgrades carefully.

Tip: When evaluating chocolate machines, look for those equipped with user-friendly interfaces and programmable settings. This can significantly reduce training time and help operators maximize productivity.

Additionally, energy efficiency is becoming a critical factor for manufacturers. Many state-of-the-art chocolate machines are designed to consume less power while maintaining high output levels. This shift not only supports sustainability efforts but also reduces operational costs, making it an attractive option for global buyers.

Tip: Assess the energy consumption of any chocolate machine before purchasing; machines with Energy Star certification or other eco-labels can save you money in the long run.

Comparative Analysis: Best Chocolate Machines on the Market Today

In the comparative analysis of the best chocolate machines currently available, it's essential to consider the specifications that cater to both consumer preferences and industry trends. The global cocoa and chocolate market is projected to reach a size of USD 10.86 billion by 2033, with a compound annual growth rate (CAGR) of 6.24%. This growth is driven by increasing consumer demand for high-quality chocolate products, prompting manufacturers to innovate continually. Consequently, the best chocolate machines must offer advanced features such as precision temperature control, efficient melting capabilities, and versatility in forming various chocolate types, meeting the standards set by discerning global buyers.

Additionally, transparency in the craft chocolate industry is becoming paramount. A recent study examined how artisan chocolatiers define sourcing practices, highlighting the growing consumer demand for ethically sourced cocoa. This shift in consumer awareness places pressure on manufacturers to provide machines that not only produce excellent chocolate but also align with sustainable practices. As competition intensifies, particularly among key players in the market, businesses investing in high-quality chocolate machines with a focus on sustainability and transparency are likely to capture a larger market share. Understanding these dynamics is crucial for global buyers in selecting the right equipment for their chocolate-making endeavors.

Exploring the Technical Specifications of the Best Chocolate Machine for Global Buyers

| Model | Weight (kg) | Dimensions (cm) | Capacity (kg) | Power (W) | Temperature Range (°C) | Price (USD) |

|---|---|---|---|---|---|---|

| Model A | 25 | 50 x 40 x 60 | 10 | 1200 | 30-60 | 2000 |

| Model B | 30 | 55 x 45 x 65 | 15 | 1500 | 25-65 | 2500 |

| Model C | 20 | 40 x 35 x 50 | 8 | 1000 | 20-55 | 1500 |

| Model D | 27 | 52 x 42 x 62 | 12 | 1300 | 28-58 | 2200 |

Sustainability Trends Impacting Chocolate Machine Manufacturing

As the chocolate industry evolves, sustainability has emerged as a crucial trend influencing the manufacturing of chocolate machines. Many global buyers are now seeking equipment that not only enhances productivity but also aligns with eco-friendly practices. This shift is prompting manufacturers to innovate their designs with a focus on energy efficiency and waste reduction. For instance, advanced chocolate machines are being developed to minimize energy consumption during the production process, which not only lowers operational costs but also reduces the carbon footprint associated with chocolate manufacturing.

Furthermore, sustainable sourcing of materials is gaining importance in the construction of chocolate machines. Manufacturers are increasingly incorporating recycled or biodegradable materials, favoring processes that lengthen the lifespan of machines while minimizing environmental impact. This shift reflects a broader commitment to sustainability within the chocolate industry, appealing to conscientious consumers and businesses alike. As the market for sustainable chocolate continues to grow, manufacturers that invest in sustainable machine technologies will likely lead the way in meeting the demands of environmentally aware buyers.

Chocolate Machine Manufacturing Sustainability Trends

Buying Guide: Evaluating the Cost-Effectiveness of Chocolate Machines

When considering the purchase of a chocolate machine, evaluating cost-effectiveness plays a pivotal role in the decision-making process. Buyers must assess the initial investment against potential long-term savings and return on investment. It's essential to analyze not only the upfront costs but also the operational expenses, including energy consumption, maintenance, and ingredient sourcing. A machine that might seem pricey at first could prove to be more efficient in production, ultimately saving money in bulk production or reducing waste.

In addition to the financial aspects, the technical specifications of the machine are crucial. Features such as production capacity, energy efficiency, and ease of use should be carefully compared across different models. Potential buyers should also look at reviews and ratings to understand how these machines perform in real-world conditions. By balancing cost with quality and performance, buyers can make informed decisions that align with their business needs and budget constraints. This thoughtful approach will ensure satisfaction and efficiency in chocolate production for years to come.