7 Tips for Choosing the Best Chocolate Enrobing Machines with 85 Percent Efficiency

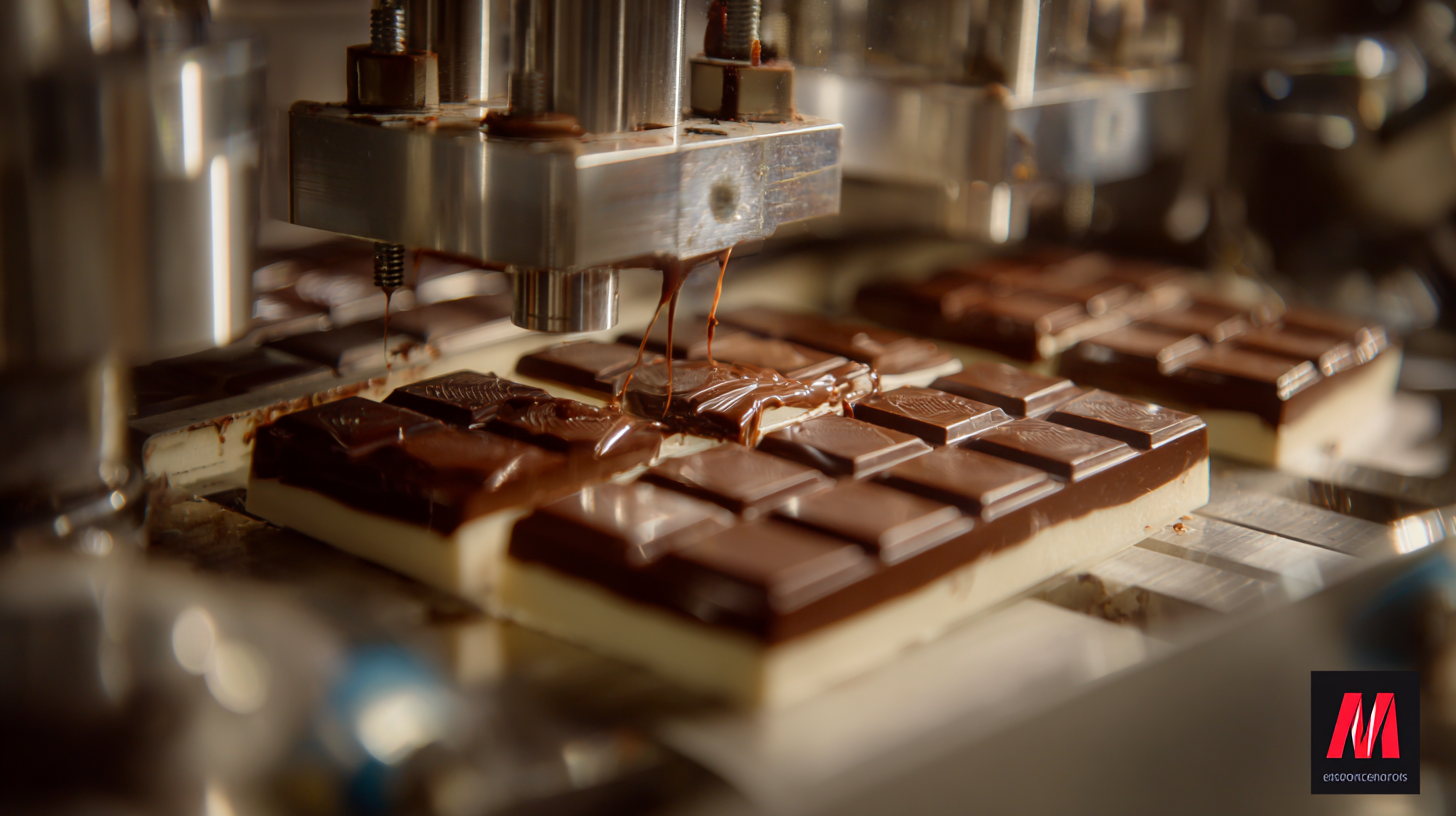

In the rapidly evolving confectionery industry, the demand for high-quality chocolate products continues to rise, prompting manufacturers to seek out efficient production solutions. According to a recent industry report, the global chocolate market is projected to reach $161 billion by 2024, with an increasing focus on artisanal and premium offerings. As a result, chocolate enrobing machines have become essential tools for producers aiming to achieve consistency and quality in their products while optimizing manufacturing processes. With efficiency rates nearing 85 percent, these machines can greatly enhance production capacity while minimizing waste.

Choosing the right chocolate enrobing machine is critical for any chocolatier looking to stay competitive in this booming market. This blog will present seven key tips to guide you in selecting the best equipment that meets your operational needs and maximizes your investment.

Key Features to Consider for Optimal Chocolate Enrobing Machines

When selecting an optimal chocolate enrobing machine, it's essential to consider several key features that directly impact efficiency and product quality. One significant aspect is the temperature control system. A machine with precise temperature management ensures even coating and prevents chocolate from seizing or becoming granular during the process. Additionally, an adjustable conveyor speed is crucial; it allows for greater flexibility in production, accommodating various product sizes and ensuring a uniform enrobing layer.

Another important consideration is the machine’s capacity and size. Look for enrobing machines that can handle your production volume without sacrificing efficiency. A machine that operates with at least 85 percent efficiency not only maximizes productivity but also maintains high-quality standards. Furthermore, pay attention to the ease of cleaning and maintenance; machines designed for quick disassembly will save time and reduce downtime between production runs. By focusing on these features, you can significantly enhance your chocolate production process.

Understanding the Importance of Efficiency in Chocolate Production

Efficiency in chocolate production is paramount for maintaining quality while maximizing output. In today’s competitive market, the right chocolate enrobing machine can significantly influence production efficiency. Choosing a machine that operates at 85 percent efficiency isn’t just about speed; it's about ensuring that every step of the production process is optimized, reducing waste and energy consumption. A machine that meets these efficiency standards can enhance the overall quality of the product, offering a consistent texture and flavor that keeps customers coming back.

When selecting an enrobing machine, consider the type of chocolate you intend to use. Different machines have various settings that cater to specific chocolate compositions. Additionally, assessing the machine’s maintenance requirements is crucial; regular upkeep not only ensures longevity but also contributes to sustained efficiency over time. Lastly, evaluating the machine's throughput capacity can help ensure that it meets your production demands without compromising quality.

By focusing on these key elements, manufacturers can significantly improve their chocolate production processes. Embracing efficiency doesn’t just lead to increased profit margins; it also sets a standard for quality that resonates with consumers, making it a worthwhile investment.

Efficiency Comparison of Chocolate Enrobing Machines

This chart illustrates the efficiency percentage of various chocolate enrobing machines. Choosing a machine with higher efficiency can significantly enhance production quality and reduce operational costs.

Trends in Chocolate Enrobing Technology for 2025 and Beyond

As the chocolate industry continues to evolve, the technology surrounding chocolate enrobing is set to experience significant advancements by 2025 and beyond. One prominent trend is the integration of automation and artificial intelligence in enrobing machines, which can enhance consistency and quality. These innovations not only speed up production but also reduce waste, allowing manufacturers to achieve higher efficiency ratings. Emphasizing sustainability in manufacturing processes will likely become crucial in the coming years, as consumers increasingly prefer products that align with eco-friendly values.

Moreover, the customization capabilities of chocolate enrobing machines are expected to expand. The demand for unique flavors and textures has inspired manufacturers to create machines that can easily adapt to various recipes and ingredients. This flexibility will enable chocolatiers to experiment with different coatings and fillings, facilitating more innovative product offerings. As we look ahead, investing in cutting-edge enrobing technology will be essential for companies aiming to stay competitive in the ever-growing chocolate market. The role of digitization, predictive maintenance, and enhanced user interfaces will pave the way for smarter and more efficient production lines.

Evaluating the Cost vs. Benefits of Advanced Enrobing Machines

When considering the purchase of advanced chocolate enrobing machines, it's essential to evaluate the cost versus the benefits carefully. Investing in a machine that offers 85 percent efficiency may seem costly upfront, but the long-term advantages can significantly outweigh the initial expenditure.

For instance, a machine with higher efficiency can reduce waste and save on material costs, ultimately leading to increased profit margins for your chocolate business.

One important tip is to examine the machine's adaptability. A versatile enrobing machine can handle various products beyond chocolate, allowing for a broader range of offerings in your product line and justifying the investment. Additionally, prioritize machines that come with robust customer support and training. This can save time and frustration in the long run, particularly when adopting new technology.

Another critical aspect to consider is the integration of automation features. Automated enrobing machines not only enhance production speed but also ensure consistent quality, which is vital in maintaining brand reputation. Look for machines with easy-to-use controls and options for scaling operations. These features can help you maximize both productivity and efficiency, making your investment worthwhile.

How to Select the Right Machine for Your Specific Chocolate Needs

When selecting the right chocolate enrobing machine for your specific needs, it's essential to evaluate several key factors that can greatly impact production efficiency and product quality. According to a recent report by the International Confectionery Association, the chocolate enrobing market is projected to grow at a CAGR of 5.2% through 2025, which underscores the increasing demand for efficient enrobing technologies. With this growth, manufacturers are focusing on machinery that not only meets production demand but also enhances overall chocolate flavor and texture.

One of the critical aspects to consider is the machine's temperature control capability. A report from the Cocoa Marketing Company highlights that maintaining an optimal temperature during the enrobing process can improve the shelf life and sensory qualities of chocolate by up to 30%. Additionally, the choice of materials in the machine construction impacts the consistency of the enrobing layer; for instance, stainless steel is favored for its durability and ease of cleaning, which is crucial for maintaining hygiene in chocolate processing. By paying attention to these details, businesses can choose enrobing machines that align with their specific chocolate specifications, ultimately leading to a more successful manufacturing process.