Top 10 Chocolate Depositing Machines for Perfect Confectionery Results

In the ever-evolving world of confectionery, the significance of precision and efficiency cannot be overstated. As industry experts highlight, the use of a "Chocolate depositing machine" has transformed production processes, allowing for the creation of intricate designs and consistent quality in chocolate confections. Renowned chocolatier and automation expert, Dr. Emily Rousseau, emphasizes this point by stating, "Investing in a high-quality chocolate depositing machine is crucial for any chocolatier looking to enhance their production capabilities while maintaining the artistry of their craft."

With the rise of customization in the chocolate industry, manufacturers are increasingly turning to advanced depositing machines that offer versatility and reliability. These machines are designed to cater to the unique demands of various chocolate products, enabling confectioners to achieve perfect results every time. From elegant molded chocolates to delectable filled treats, the potential of a chocolate depositing machine is limitless.

In this article, we explore the top 10 chocolate depositing machines that promise to deliver excellence in confectionery results. By examining their features and capabilities, we aim to provide valuable insights for chocolate makers who aspire to refine their craft and elevate their production standards. The path to creating remarkable chocolate creations begins with the right tools, and a superior chocolate depositing machine is undoubtedly one of the key ingredients.

Understanding Chocolate Depositing Machines and Their Importance

Chocolate depositing machines play a crucial role in the confectionery industry, streamlining the process of producing high-quality chocolate products. These machines are specifically designed to dispense liquid chocolate into molds, ensuring uniformity and precision in every creation. By controlling variables such as temperature and flow rate, chocolate depositing machines help maintain the chocolate's consistency, crucial for achieving the desired texture and flavor. Their ability to automate the depositing process minimizes human error, enhances productivity, and enables manufacturers to meet high-volume demands efficiently.

Understanding the importance of chocolate depositing machines also involves acknowledging their impact on product innovation. With advancements in technology, these machines have incorporated features that allow for intricate designs and the customization of chocolate shapes and sizes. This flexibility encourages confectioners to experiment and bring unique products to market, satisfying evolving consumer tastes. Additionally, the ease of operation and maintenance of these machines contribute to improved workflow in production facilities, making them an essential investment for any chocolate-making business aiming for perfection in their confectionery results.

Key Features to Consider When Choosing a Chocolate Depositing Machine

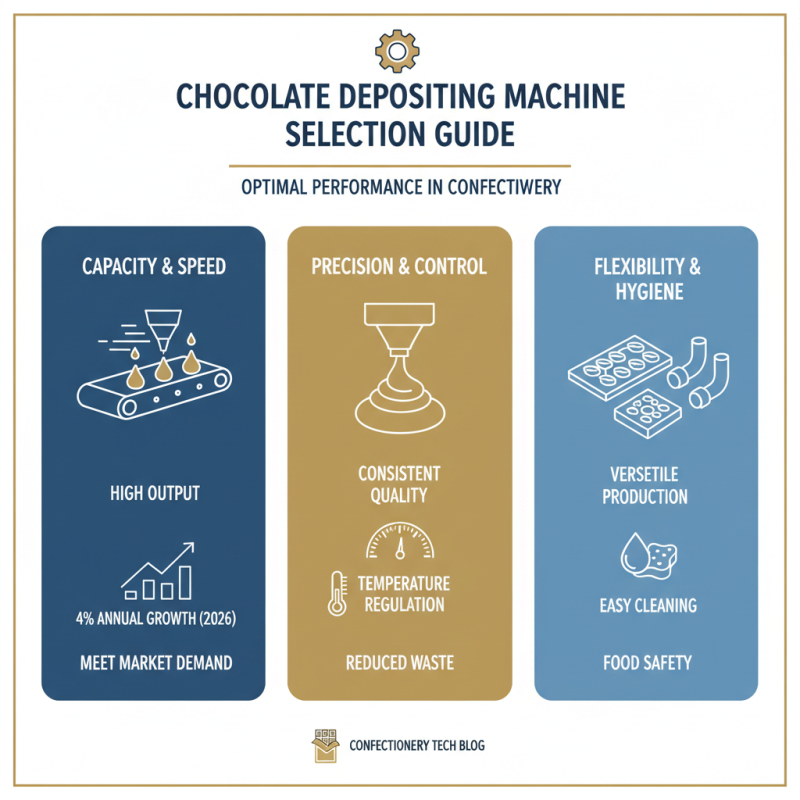

When selecting a chocolate depositing machine, several key features must be evaluated to ensure optimal performance in confectionery production. One critical aspect is the machine’s capacity and speed. According to a report by Freedonia Group, the demand for automated confectionery equipment, including depositing machines, is expected to grow by more than 4% annually through 2026. Machines capable of depositing chocolate at high speeds not only increase output but also help maintain product quality, allowing businesses to respond better to market demands.

Another crucial feature to consider is temperature control. The chocolate manufacturing process is sensitive to temperature fluctuations, which can affect the consistency and final quality of the product. Machines equipped with advanced temperature management systems ensure that chocolate is maintained within the ideal range, thus preventing issues like bloom and ensuring a smooth finish. Industry data from the International Confectionery Association indicates that maintaining precise temperature control in chocolate production can enhance shelf life and consumer satisfaction, directly impacting sales and profitability.

Additionally, versatility in product design is a significant consideration. A machine that can easily switch between various chocolate types and shapes offers substantial competitive advantages. Reports suggest that consumer preferences are increasingly leaning towards personalized and specialty chocolates, with custom-shaped confections seeing a rise in popularity. Investing in a machine that accommodates diverse molds and chocolate formulations can help manufacturers stay ahead of market trends and fulfill customer demands effectively.

Top 10 Chocolate Depositing Machines: A Comprehensive Overview

When it comes to confectionery production, precision and efficiency are paramount.

Chocolate depositing machines have revolutionized the way chocolate is used in manufacturing, allowing for

consistent, high-quality results. These machines automate the process of depositing melted chocolate into molds,

which helps streamline production and reduce labor costs. With a variety of models available, it's essential to

understand the different features and capabilities that each machine offers to determine the best fit for

specific production needs.

In the realm of chocolate depositing technology, factors such as temperature control,

speed, and ease of cleaning play a crucial role

in selecting the right machine. Advanced models are equipped with features that ensure precise dosing and

even distribution of chocolate, which is vital for achieving uniform results in confectionery shaping.

Additionally, the versatility of these machines allows them to handle various types of chocolate, encompassing

dark, milk, and white chocolate, along with inclusions like nuts or fruits. Understanding these functionalities

enables manufacturers to optimize their production processes while maintaining the high standards

expected in the confectionery market.

Comparative Analysis of Performance and Efficiency in Chocolate Machines

When it comes to chocolate depositing machines, the performance and efficiency of these machines are pivotal in determining the quality of the final confectionery products. According to the Confectionery Equipment Manufacturers Association (CEMA), the efficiency of chocolate depositing systems has improved significantly, achieving output increases of up to 30% in the last decade. This enhancement is largely due to advancements in technology, such as precise temperature control and faster conveyor systems, which allow for a uniform flow and better handling of chocolate during the depositing process. Machines equipped with smart sensors can also adjust speeds in real time, ensuring consistent product quality.

For manufacturers looking to optimize their production, several factors need to be considered. The size of the depositor, the speed of operation, and the ease of maintenance play crucial roles in overall efficiency. In fact, a recent industry report indicated that machines offering modular designs can reduce downtime by 20% during maintenance, making them a cost-effective solution in the long run. Additionally, investing in machines that utilize advanced heating methods can result in lower energy consumption, further enhancing operational sustainability.

Tips: When selecting a chocolate depositing machine, prioritize energy efficiency and ease of use. Regular maintenance checks are also essential to prolong the machine’s lifespan, ensuring that you continue to produce high-quality confectionery without interruption. Always consider the scalability of your equipment to accommodate future production demands.

Top 10 Chocolate Depositing Machines for Perfect Confectionery Results

| Machine Model | Production Capacity (kg/h) | Depositing Accuracy (%) | Heating System (°C) | Energy Consumption (kWh) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 250 | 98 | 45 | 2.5 | 10,000 - 12,000 |

| Model B | 300 | 95 | 50 | 3.0 | 8,000 - 10,000 |

| Model C | 200 | 97 | 40 | 2.0 | 12,000 - 15,000 |

| Model D | 350 | 96 | 55 | 3.5 | 15,000 - 18,000 |

| Model E | 280 | 99 | 48 | 2.8 | 13,000 - 16,000 |

| Model F | 320 | 94 | 53 | 3.2 | 11,000 - 14,000 |

| Model G | 230 | 97 | 42 | 2.4 | 9,000 - 11,000 |

| Model H | 260 | 99 | 44 | 2.9 | 10,500 - 13,500 |

| Model I | 300 | 95 | 50 | 3.1 | 12,500 - 15,500 |

| Model J | 240 | 98 | 47 | 2.7 | 11,000 - 13,000 |

Best Practices for Operating Chocolate Depositing Machines for Quality Results

When operating chocolate depositing machines, adhering to best practices is essential for achieving high-quality results. First and foremost, it's important to ensure that the machine is properly calibrated. This includes checking the temperature settings, as chocolate needs to be melted to a specific degree to allow for smooth depositing. Additionally, maintaining a consistent viscosity is crucial; this can be achieved by monitoring the temperature and utilizing the machine's functionality to keep the chocolate at the ideal flow rate. Regular cleaning of the machine also contributes to better results, as any residue or buildup can affect the final product's appearance and taste.

Another significant practice involves careful monitoring during production runs. Operators should frequently check for any irregularities in the depositing process, as even minor inconsistencies can lead to defects in the finished confectionery. It is also beneficial to experiment with different depositing techniques, such as adjusting the speed and pressure, to find the optimal settings for various chocolate types and product designs. Implementing routine maintenance and following the manufacturer's guidelines can further enhance the machine's performance, ensuring reliability and quality in chocolate production.

Chocolate Depositing Machine Performance Comparison

Related Posts

-

Unlocking the Sweet Secrets: How Chocolate Depositing Machines Revolutionize Confectionery Production

-

Ultimate Guide to Choosing the Right Chocolate Depositing Machine for Your Business Needs

-

Revolutionizing Confectionery: How Chocolate Depositing Machines are Shaping the Future of Sweet Treats

-

Ultimate Guide to Choosing the Right Chocolate Depositing Machine for Your Factory

-

Discover Cutting Edge Chocolate Depositing Machines at the 137th Canton Fair 2025

-

7 Essential Tips for Choosing the Best Chocolate Molding Machine for Your Factory